Shenzhen Electronics Cluster: Key Advantages for Electronic Consumer Goods Buyers

Shenzhen Electronics Cluster: 5 Proven Advantages to Streamline Your Electronic Consumer Goods Procurement

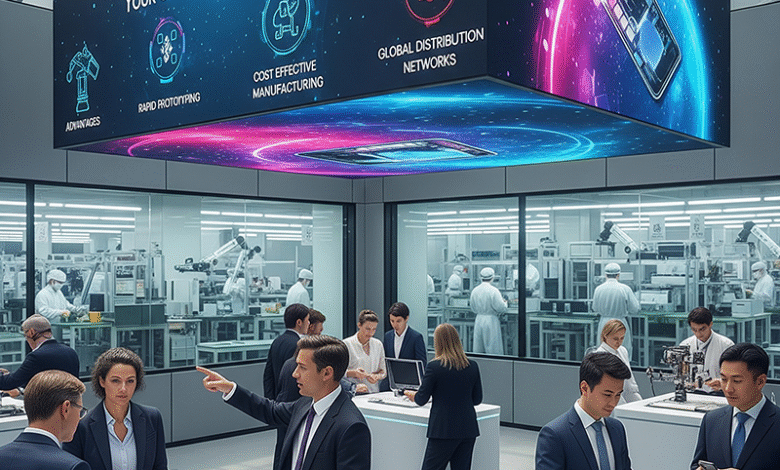

In the global electronic consumer goods market, Shenzhen’s electronics industry cluster stands out as a trusted, go-to destination for smart procurement. As a hub for efficient manufacturing, rapid innovation, and seamless supply chain integration, it directly addresses the core needs of electronic consumer goods buyers—from cutting costs to fast delivery and flexible customization. For buyers seeking reliable partners to source smartphones, wearables, home appliances, or IoT devices, understanding Shenzhen’s unique traits is critical to streamlining procurement and gaining a competitive edge in tight markets.

1. Ultra-Integrated Supply Chain: Your One-Stop Procurement Solution

The biggest advantage of Shenzhen’s electronics cluster is its end-to-end supply chain integration—a game-changing benefit for electronic consumer goods buyers. Unlike scattered manufacturing regions, Shenzhen brings every link of the production process within easy reach:

- Component suppliers: From microchips (e.g., local leaders like Huawei HiSilicon or global brands like Qualcomm with local offices) to batteries, screens, and connectors, buyers can source 90%+ of electronic components within a 50-kilometer radius. This eliminates frustrating delays from cross-region shipping and slashes logistics costs.

- Contract manufacturers (CMs): Leading CMs such as Foxconn, BYD Electronics, and Jabil run large-scale, efficient facilities in Shenzhen, offering turnkey services—from prototyping to mass production. For buyers, this means no need to juggle multiple vendors; one trusted partner handles design, assembly, and strict testing.

- Auxiliary services: Nearby industrial parks also host reliable packaging suppliers, top-tier quality inspection labs (e.g., SGS, TÜV SÜD branches), and fast logistics firms (SF Express, DHL’s Shenzhen hub). This “one-stop” ecosystem cuts procurement cycles by 30–40% compared to sourcing from dispersed regions.

For example, a buyer looking to launch a new smartwatch can meet with component suppliers in the morning, review polished prototypes at a CM in the afternoon, and finalize eye-catching packaging designs the next day—all without leaving Shenzhen.

2. Cost Efficiency: Competitive Pricing for Bulk & Small-Batch Orders

Electronic consumer goods buyers—whether sourcing large bulk orders or testing small batches—gain real value from Shenzhen’s strong cost competitiveness. This comes from two key factors:

- Economies of scale: With over 100,000 registered electronics-related businesses (as of 2024) competing and collaborating, suppliers can lower unit costs by producing high volumes. For bulk orders (e.g., 10,000+ smartphones), buyers often secure 15–25% lower prices than in non-clustered regions—freeing up budget for other priorities.

- Reduced waste: The short distance between suppliers and manufacturers minimizes costly material waste from transportation damage. It also allows for quick, real-time adjustments—if a component is defective, a replacement arrives within hours, avoiding expensive production halts.

Even small-batch buyers (e.g., startups sourcing 500–1,000 IoT devices) win here. Many Shenzhen suppliers offer “low MOQ (minimum order quantity)” options—thanks to the cluster’s flexible production capacity—letting you test market demand without overinvesting.

3. Rapid Innovation & Tech Adaptability: Stay Ahead of Fast Market Trends

The electronic consumer goods industry moves at lightning speed—trends like foldable screens, AI-integrated devices, and eco-friendly materials pop up yearly. Shenzhen’s cluster excels at fast innovation and agile tech adoption, keeping your products relevant and in demand:

- R&D density: Shenzhen spends over 5% of its GDP on R&D (far above the global average for industrial cities), with most investment focused on consumer electronics. Local universities (e.g., Southern University of Science and Technology) and research centers partner closely with manufacturers to turn new tech into sellable products quickly.

- Agile production: Suppliers in the cluster are skilled at adapting to new specs. For instance, when wireless charging became a must-have for smartphones, Shenzhen CMs updated their assembly lines in weeks—faster than manufacturers in slower-moving regions.

- Access to new tech: You can easily collaborate with local firms to integrate cutting-edge features (e.g., 5G modules, biometric sensors) into your products. This reduces the risk of launching outdated goods and helps you capture early market share.

4. Strict Quality Control & Compliance: Mitigate Costly Procurement Risks

For electronic consumer goods buyers, quality and compliance are non-negotiable—especially when selling to global markets (e.g., EU, US, Southeast Asia) with strict rules. Shenzhen’s cluster prioritizes top-tier quality standards and full compliance to keep your business safe:

- Third-party inspection support: As mentioned earlier, global inspection firms (SGS, BV) have a strong presence in Shenzhen. You can arrange on-site quality checks at any production stage, ensuring products meet CE, FCC, RoHS, or other regional standards—no surprises later.

- Supplier accountability: The cluster’s competitive environment pushes suppliers to maintain high quality. Poor-performing vendors risk losing business to rivals, so most invest in trusted quality management systems (QMS) like ISO 9001.

- Transparency: Many Shenzhen manufacturers share real-time production data (via user-friendly cloud tools) with you, letting you track progress and spot quality issues early. This transparency reduces the risk of receiving non-compliant goods and simplifies post-purchase support.

5. Fast Turnaround Times: Meet Tight Market Deadlines

In electronic consumer goods, speed to market can make or break your success—especially for seasonal products (e.g., holiday gadgets) or sudden demand spikes. Shenzhen’s cluster delivers impressively fast turnaround times to keep you on track:

- Short lead times: For standard products (e.g., basic wireless earbuds), lead times from order to delivery can be as short as 2–4 weeks. For customized products, it’s often 6–8 weeks—far faster than sourcing from regions like Southeast Asia (10–12 weeks) or Europe (12–16 weeks).

- Logistics excellence: Shenzhen’s ports (Yantian, Shekou) and airports (Shenzhen Bao’an International) are among the world’s busiest, offering direct shipping to 200+ countries. You can choose air freight (for urgent orders) or sea freight (for cost-saving bulk shipments) with minimal delays.

- Crisis resilience: The cluster’s integrated supply chain helps during disruptions. For example, during component shortages, local suppliers can quickly switch to approved alternatives (with your go-ahead) to keep production on track—something hard to do with dispersed supply chains.

Why Shenzhen’s Cluster Is a Must for Smart Electronic Consumer Goods Buyers

For electronic consumer goods buyers, Shenzhen’s electronics cluster isn’t just a manufacturing hub—it’s a strategic, reliable partner that solves your biggest procurement headaches:

- Cuts costs and logistics time with a seamless, integrated supply chain.

- Offers flexibility for both bulk and small-batch orders, no matter your business size.

- Keeps your products innovative and compliant with global standards, reducing risk.

- Delivers fast turnaround times to seize market opportunities before competitors.

Whether you’re a large retailer sourcing millions of devices or a startup launching your first product, Shenzhen’s cluster provides the resources, speed, and trust you need to succeed in the competitive electronic consumer goods market.