How Buyers Can Effectively Manage Their Supply Chain

In today’s dynamic global marketplace, a well-managed supply chain is no longer just a logistical necessity for buyers – it’s a critical competitive advantage. For procurement professionals, effectively overseeing the entire supply chain, from raw material sourcing to final product delivery, is paramount for ensuring efficiency, cost savings, and sustained business success. This article will outline key strategies for buyers to proactively manage their supply chain.

1. Strategic Supplier Relationship Management (SRM)

Beyond mere transactional interactions, buyers must cultivate strong, collaborative relationships with their suppliers. This involves:

- Tiered Categorization: Classify suppliers based on their strategic importance (e.g., critical, tactical, commodity). This allows for differentiated management efforts, focusing more resources on key partners.

- Clear Communication & Expectations: Establish unambiguous contracts, service level agreements (SLAs), and performance metrics. Regularly communicate current and future needs, and provide constructive feedback.

- Joint Problem Solving & Innovation: Collaborate with key suppliers on design, process improvements, and even new product development. This fosters a sense of partnership and can lead to mutually beneficial innovations.

- Supplier Development: For high-potential suppliers, offer support, training, or resources to help them improve their capabilities, quality, or efficiency.

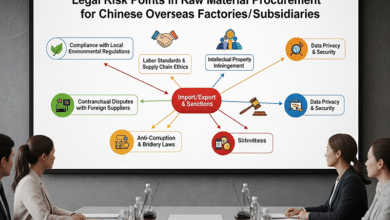

2. Robust Risk Management and Resilience

Supply chains are inherently vulnerable to disruptions – natural disasters, geopolitical events, economic downturns, or even a single supplier’s failure. Buyers must build resilience:

- Risk Assessment and Mapping: Identify potential risks across the entire supply chain, from raw material origins to transportation routes. Map out your supply chain to understand interdependencies.

- Diversification of Suppliers: Avoid single-sourcing, especially for critical components. Cultivate a diverse supplier base across different geographies to mitigate location-specific risks.

- Contingency Planning: Develop detailed backup plans for key components or services. This might include maintaining buffer stock, having alternative suppliers pre-qualified, or exploring near-shoring/reshoring options.

- Early Warning Systems: Implement systems for real-time monitoring of global events, supplier financial health, and relevant industry news to anticipate potential disruptions.

3. Data-Driven Decision Making

Leveraging data analytics is crucial for optimizing supply chain performance:

- Performance Metrics (KPIs): Track key performance indicators such as on-time delivery, quality defect rates, lead times, cost per unit, and supplier responsiveness.

- Demand Forecasting Accuracy: Collaborate internally with sales and marketing teams to improve demand forecasting. Accurate forecasts reduce overstocking or stockouts.

- Spend Analysis: Regularly analyze procurement spend to identify areas for cost reduction, consolidation, or negotiation leverage.

- Technology Adoption: Utilize supply chain management (SCM) software, enterprise resource planning (ERP) systems, and potentially AI/machine learning tools for predictive analytics, automation, and enhanced visibility.

4. Ethical and Sustainable Sourcing

Beyond cost and efficiency, modern buyers are increasingly responsible for ensuring ethical and sustainable practices throughout their supply chain:

- Supplier Audits: Conduct regular audits to verify compliance with labor laws, environmental regulations, and ethical standards.

- Code of Conduct: Implement a clear supplier code of conduct that outlines expectations regarding human rights, environmental protection, and anti-corruption.

- Traceability: Strive for greater transparency and traceability of materials and components to ensure they are sourced responsibly.

- Collaboration with Industry Initiatives: Participate in industry-wide efforts or certifications that promote sustainable and ethical supply chains.

5. Inventory Optimization

Managing inventory levels effectively is a delicate balance between meeting demand and minimizing carrying costs:

- Just-in-Time (JIT) vs. Just-in-Case: Determine the optimal inventory strategy based on product characteristics, demand volatility, and supplier reliability.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): Work closely with key suppliers to synchronize forecasting and replenishment activities, reducing inventory holding costs for both parties.

- Safety Stock Levels: Calculate appropriate safety stock levels to buffer against unexpected demand fluctuations or supply disruptions without excessive inventory.

For today’s procurement professionals, supply chain management is an evolving discipline that demands strategic thinking, strong relationships, data proficiency, and a commitment to ethical practices. By focusing on strategic supplier management, building resilience, leveraging data, championing sustainability, and optimizing inventory, buyers can transform their supply chain from a cost center into a powerful engine for business growth and competitive advantage.