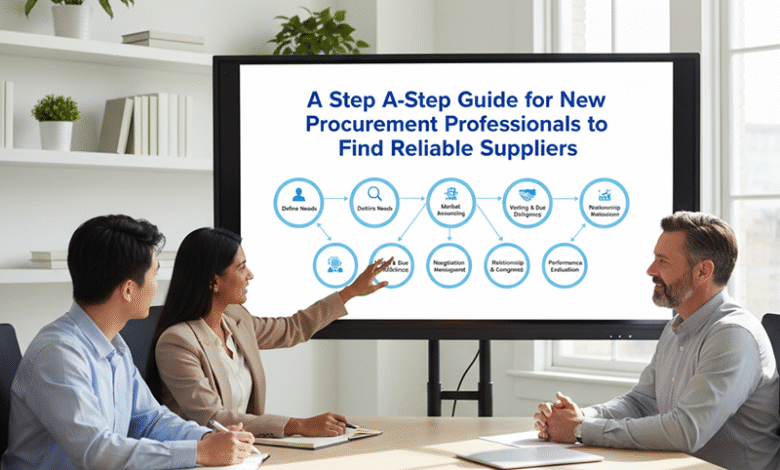

A Step-by-Step Guide for New Procurement Professionals to Find Reliable Suppliers

Introduction

For new procurement professionals, finding reliable suppliers is not a random, ad-hoc task—it is a systematic process that requires mastering three core competencies:

- Channel Expansion: Identifying diverse, high-quality sources of potential suppliers.

- Professional Evaluation: Assessing suppliers’ core capabilities to ensure alignment with business needs.

- Collaboration Risk Management: Mitigating risks during the collaboration lifecycle, from trial orders to long-term partnerships.

This guide summarizes industry-proven, practical tips to help you build a stable, efficient supplier network quickly.

1. Efficient Supplier Channel Expansion: 3 Key Tactics

The first critical step in supplier development is expanding your search channels strategically. Focus on the following three high-impact methods to avoid missing out on reliable candidates:

1.1 Precision Screening on Mainstream B2B Platforms

B2B platforms are the most accessible starting point for sourcing, as they aggregate a large number of verified suppliers. Choose platforms based on your product needs:

- General B2B Platforms: Ideal for sourcing common products (e.g., raw materials, standard components), such as:

- Alibaba: Offers “Gold Supplier” and “Trade Assurance” filters to verify supplier credibility.

- Made-in-China.com: Features “On-Site Checked” suppliers (factories inspected by third-party teams).

- Vertical Industry Platforms: For specialized or technical products (e.g., electronic components, medical devices), use niche platforms to save vetting time:

- Digi-Key: Specializes in electronic components, with detailed product specs and supplier qualification data.

- Thomasnet: Focuses on industrial parts and custom manufacturing, connecting buyers with industry-specific suppliers.

- Industry-specific portals (e.g., PharmaSource for pharmaceutical raw materials): Tailored to regulated industries, ensuring suppliers meet sector-specific standards.

1.2 Deep Mining at Offline Scenes

Offline resources allow you to verify suppliers’ capabilities in person and build initial trust. Prioritize these opportunities:

- Industry Exhibitions & Trade Shows:

- Global/Regional Shows: Canton Fair (Guangzhou, China), Hannover Messe (Germany), Import and Export Fair (China), and National Hardware Show (USA) – these events let you inspect product samples, meet supplier teams, and discuss collaboration details face-to-face.

- Niche Industry Shows: For specialized sectors (e.g., automotive parts, renewable energy), attend shows like Auto Parts Expo or Intersolar – they attract suppliers with deep expertise in your field.

- Government & Chamber of Commerce Resources:

- Local Commerce Bureaus: Provide lists of certified “high-integrity suppliers” (especially for domestic sourcing in China).

- Industry Associations: Organizations like the China Council for the Promotion of International Trade (CCPIT) or the National Association of Purchasing Management (NAPM) host supplier matchmaking events and share verified vendor directories.

- Foreign Trade Chambers: For cross-border sourcing, chambers like the American Chamber of Commerce (AmCham) in China can recommend local suppliers with export experience.

1.3 Leveraging Networks and Competitor Intelligence

Internal and industry insights often lead to “hidden gem” suppliers that are not easily found on public platforms:

- Internal Referrals:

- Collaborate with engineers, production managers, and senior buyers in your company. Engineers, in particular, stay updated on industry technology trends and can recommend high-quality suppliers in niche segments (e.g., custom mold manufacturers, specialized material suppliers).

- Use internal project records: Review past procurement reports to identify suppliers that performed well for other departments.

- Competitor Supplier Analysis:

- Study public data: Analyze competitors’ financial reports (for listed companies), product packaging (supplier names may be printed on components), and industry research reports (e.g., from Statista or IBISWorld) to identify their key suppliers.

- Target alternative vendors: Once you identify a competitor’s supplier, research other suppliers in the same industrial cluster or supply chain – these vendors often meet similar quality and delivery standards but may offer more flexible terms (e.g., lower MOQs for small buyers).

2. Professional Supplier Evaluation: Verify Core Capabilities

After shortlisting potential suppliers, conduct a thorough evaluation to avoid partnering with vendors that cannot meet your needs. Focus on the following four key areas:

2.1 On-Site Visits (Critical for Core Suppliers)

Schedule visits to the supplier’s factory or warehouse to assess their actual operations:

- Production Lines: Check if equipment is well-maintained, workflows are organized, and production capacity matches their claims.

- Quality Control (QC) Processes: Observe if there are dedicated QC teams, whether tests are conducted at key production stages (e.g., incoming materials, final inspection), and if QC records are properly kept.

- Warehouse Management: Ensure raw materials and finished goods are stored safely (especially for perishable or hazardous materials) and that inventory levels are reasonable (to avoid delivery delays).

- Compliance: Verify if the supplier has necessary certifications (e.g., ISO 9001 for quality, ISO 14001 for environmental management) and if their facilities meet local labor and safety regulations.

2.2 Financial Health Checks

A financially unstable supplier may delay orders or even cease operations, leading to supply chain disruptions. Assess their financial health using:

- Financial Statements: Request recent balance sheets, income statements, and cash flow reports (most reputable suppliers will provide these if you sign a non-disclosure agreement, NDA).

- Third-Party Tools: Use platforms like Dun & Bradstreet (D&B) or Credit China (for Chinese suppliers) to check credit ratings, payment histories, and any records of bankruptcy or debt defaults.

- Key Indicators: Focus on solvency (current ratio > 1.5 is ideal) and profitability (positive net profit for the past 2 years) to ensure the supplier can sustain long-term cooperation.

2.3 Quality and Capacity Assessments

- Quality Verification:

- Sample Testing: Request 2–3 batches of samples and test them against your quality standards (e.g., material composition, durability, performance). For regulated products (e.g., electronics), send samples to a third-party lab (e.g., SGS or TÜV) for certification.

- Customer References: Ask the supplier for 2–3 references from existing clients (preferably in your industry) and contact them to confirm the supplier’s quality consistency and after-sales service.

- Certification Check: Verify if the supplier holds industry-specific certifications (e.g., CE for European markets, FCC for the US, RoHS for environmental compliance).

- Capacity Evaluation:

- Current Output: Ask for data on monthly/annual production volume to confirm if they can meet your regular order needs.

- Peak-Demand Capacity: Inquire if they can increase production during your busy seasons (e.g., 20% more output for holiday orders) and if they have backup production lines for emergencies.

2.4 Flexibility Analysis

In dynamic markets, supplier flexibility is critical for adapting to changes. Evaluate:

- Order Adjustments: Can the supplier increase or decrease order quantities with short notice (e.g., 7 days for small adjustments)?

- Spec Modifications: If your product specs change, how quickly can the supplier update their production process (e.g., 2 weeks for minor design changes)?

- Expedited Delivery: What is the shortest lead time they can offer for urgent orders (e.g., 48 hours for critical components) and what is the additional cost (if any)?

3. Build Trust Before Formal Collaboration

Even if a supplier passes your evaluation, do not rush into large orders. Start with small-scale collaboration to align expectations and build trust:

3.1 Preliminary Trial Cooperation

Propose a “test phase” (1–2 months is ideal) with clear goals:

- Trial Scope: Limit the trial to a small order (e.g., 5–10% of your regular order volume) or a non-critical product to reduce risk.

- Expectations: Clearly communicate delivery timelines (e.g., 10 days from order confirmation), quality standards (e.g., defect rate < 0.5%), and communication frequency (e.g., weekly progress updates).

- Feedback: After the trial, share a detailed feedback report with the supplier – highlight strengths and areas for improvement (e.g., “Delivery was on time, but packaging needs to be reinforced to prevent damage”).

3.2 Foster Friendly, Transparent Relationships

Trust is built through consistent communication:

- Designate a Contact Person: Assign a dedicated team member to communicate with the supplier’s account manager – this avoids confusion from multiple contacts.

- Regular Check-Ins: Schedule monthly calls or meetings to discuss ongoing orders, upcoming needs, and any potential issues (e.g., “We expect a 30% increase in orders next quarter – can you prepare for this?”).

- Treat Suppliers as Partners: Avoid excessive price pressure that may force the supplier to cut corners on quality. Instead, discuss win-win solutions (e.g., “If we commit to a 6-month order, can you offer a 5% discount?”).

4. Launch Collaboration and Manage Risks

Once trust is established, formalize the collaboration with a focus on risk mitigation:

4.1 Small-Batch Trial Orders

Before scaling up, place a trial order to verify the supplier’s performance in a real-world scenario:

- Order Volume: Control the first formal order to no more than 10% of your total monthly demand – this limits losses if issues arise.

- Key Metrics to Assess:

- MOQ Reasonableness: Does the supplier’s MOQ align with your needs (e.g., if you need 500 units, can they avoid forcing a 1,000-unit MOQ)?

- Urgent Order Response: Test their ability to handle rush requests by placing a small urgent order (e.g., “Can you deliver 100 units in 48 hours?”) and track their response time.

- Quality Issue Traceability: If defects are found, ask the supplier to provide a root cause analysis (RCA) and corrective action plan (CAP) – a reliable supplier will resolve issues within 3–5 days.

4.2 Prepare Backup Suppliers for Key Materials

For critical materials (e.g., core components that directly affect your product’s functionality), always develop at least 2 alternative suppliers (one primary, two backups is ideal):

- Backup Selection: Choose backup suppliers that are geographically dispersed (to avoid regional disruptions, e.g., natural disasters) and have similar quality standards to the primary supplier.

- Regular Engagement: Place small orders with backup suppliers every 3–6 months to keep the relationship active – this ensures they can prioritize your orders if the primary supplier fails.

Final Tips for New Procurement Pros

As a beginner, avoid two common mistakes: “collecting too many suppliers” (leading to scattered focus) and “rushing into large orders” (increasing risk). Instead:

- Focus on 1–2 Core Categories First: Master the sourcing process for your company’s most critical products (e.g., if you work in electronics, start with circuit boards) before expanding to other categories.

- Build a Supplier Database: Use a spreadsheet or tool (e.g., Excel, Google Sheets, or procurement software like Coupa) to document each supplier’s:

- Contact details (name, phone, email of account manager).

- Performance metrics (on-time delivery rate, defect rate, response time).

- Trial results and feedback.

- Remember the Three Golden Rules:

- Data is more reliable than intuition: Always back decisions with test results, financial data, or references.

- Written contracts are more trustworthy than verbal promises: Include clear terms for delivery, quality, payment, and liability in the contract (consult legal teams if needed).

- Backup options are safer than single reliance: Never rely on one supplier for critical materials.

Conclusion

By following this step-by-step framework – expanding channels strategically, evaluating suppliers professionally, building trust gradually, and managing risks proactively – you will build a stable, high-quality supplier network. This network will not only support your daily procurement work but also lay a solid foundation for your long-term career growth in procurement.